Introduction

The automotive industry stands on the brink of a revolution, driven by the advent of 3D printing technology. This innovative manufacturing method, traditionally associated with prototyping and small-scale production, is now reshaping the entire automotive landscape. In this article, we will explore how 3D printing is changing the game for automotive manufacturers, the benefits it brings, its limitations, and predictions for the future.

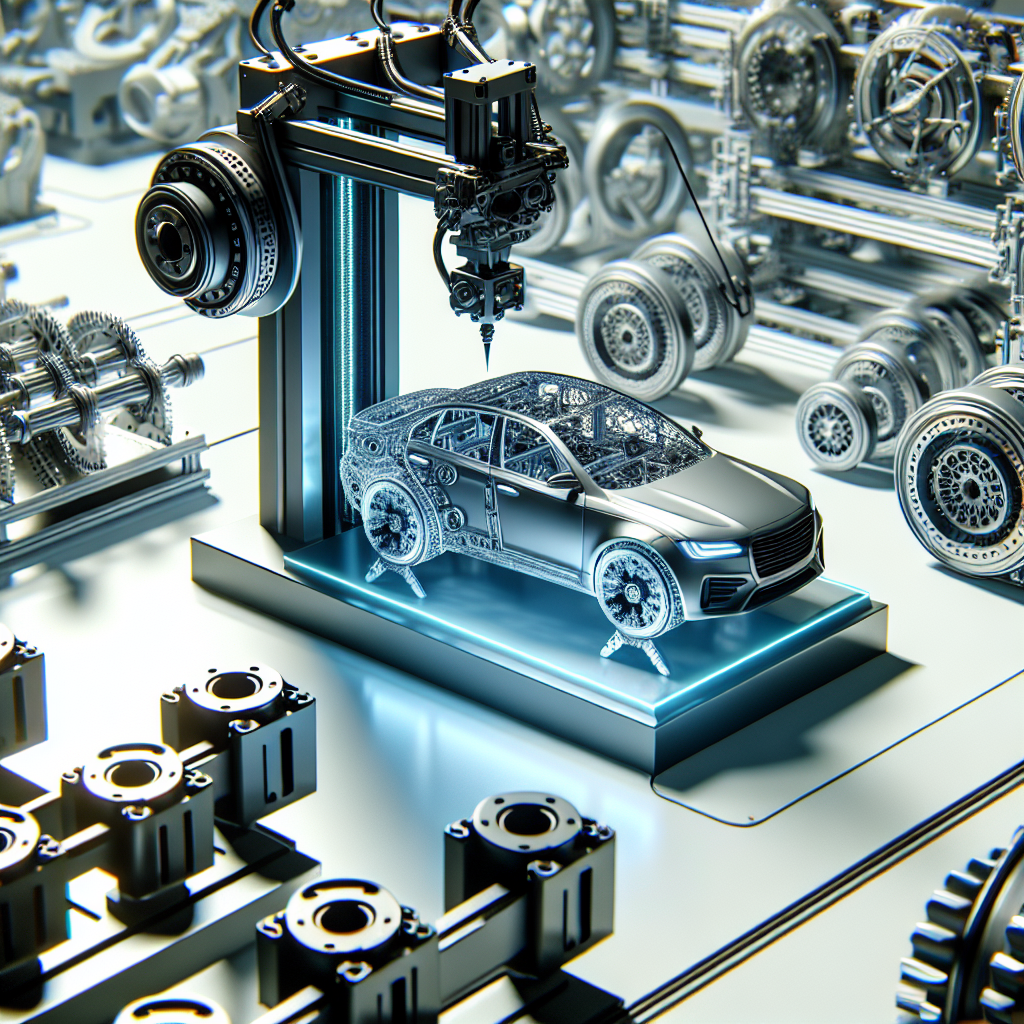

The Rise of 3D Printing in Automotive

In recent years, 3D printing has gained traction in the automotive sector, evolving from a niche tool for rapid prototyping into a core component of manufacturing processes. Recognized for its ability to create complex geometries and custom parts quickly, it allows companies to reduce lead times and costs.

Historical Context

3D printing technology dates back to the 1980s, but its integration into automotive manufacturing has accelerated in the 21st century. Early adopters like Ford and BMW began exploring its potential for creating lightweight components, thereby enhancing fuel efficiency.

How 3D Printing Works

At its core, 3D printing, or additive manufacturing, involves creating objects layer by layer from digital models. This technique contrasts sharply with traditional subtractive manufacturing, which involves cutting away material from a solid block.

Types of 3D Printing Technologies

- SLA (Stereolithography): Utilizes ultraviolet light to cure liquid resin into hardened plastic.

- FDM (Fused Deposition Modeling): Melts plastic filament and extrudes it layer by layer.

- SLS (Selective Laser Sintering): Uses a laser to sinter powdered material into a solid structure.

Advantages of 3D Printing in the Automotive Industry

1. Customization

3D printing empowers automotive manufacturers to create bespoke parts tailored to specific models or customer requests. This level of customization was often impractical with traditional manufacturing.

2. Weight Reduction

By using advanced materials and innovative designs, manufacturers can reduce vehicle weight, enhancing performance and fuel efficiency. For instance, companies like Mercedes-Benz have utilized 3D printing to produce lightweight components that improve vehicle dynamics.

3. Cost Efficiency

Although the initial investment in 3D printing technology can be high, the long-term cost savings are significant. The technology reduces material waste and lowers production costs by eliminating the need for complex tooling.

4. Rapid Prototyping

3D printing significantly shortens the time required for prototyping, allowing companies to iterate designs quickly. This accelerates the overall production timeline for new vehicles.

Challenges of 3D Printing in Automotive

1. Material Limitations

While 3D printing has advanced significantly, there are still limitations regarding the types of materials that can be used. Metal printing is particularly challenging, though advancements in technologies like SLM (Selective Laser Melting) are addressing this issue.

2. Quality Control

The quality of 3D printed parts can vary, leading to potential issues in performance and safety. Establishing rigorous quality control measures is essential for automotive applications.

3. Production Speed

While 3D printing is ideal for small batches and custom parts, mass production remains a challenge. Manufacturers are working to integrate 3D printing into assembly lines efficiently.

The Future of 3D Printing in the Automotive Industry

As we look ahead, the potential of 3D printing in the automotive industry is vast. Here are some future predictions:

1. Increased Adoption

As technology advances and becomes more affordable, expect broader adoption across the industry. Companies of all sizes will leverage 3D printing to gain a competitive edge.

2. Sustainability Focus

The automotive sector is under pressure to reduce its environmental footprint. 3D printing can contribute to sustainability through material efficiency and the ability to produce localized parts, minimizing transportation emissions.

3. Integration with AI and IoT

Future 3D printing technologies will likely integrate with artificial intelligence and the Internet of Things (IoT) for smarter manufacturing processes, optimizing production based on real-time data.

Conclusion

As 3D printing technology continues to evolve, its implications for the automotive industry are profound. From customized vehicles to sustainable practices and efficient production, the future looks bright. The automotive industry is not just adapting to this technology; it is being transformed by it. Embracing these innovations will be key to staying competitive in an ever-changing market.

Leave a Reply